Q&A: Are 3D-printed compounded medications the future of veterinary prescribing?

The cofounder of a biotech developing 3D-printing compounding technology company discusses the company's official entrance into the veterinary space, in this Q&A.

Accurately dosing medications for animal patients of different sizes and species can be a challenge. Traditional compounding can be imprecise, often relying on manual adjustments or requiring pet owners to split tablets, which can introduce variability. Now, a Finnish biotechnology company, CurifyLabs, is bringing 3D-printed compounded medications to the veterinary space after years in human compounding pharmacies and hospitals.

In this Q&A, adapted from an interview with dvm360, Niklas Sandler Topelius, PhD, MSc, chief technology officer and cofounder of CurifyLabs, explains how the company’s

Editor’s note: This dvm360 Q&A has been edited and consolidated from a verbal interview to better fit a written format while retaining the substance of the original conversation.

dvm360: Can you tell us about CurifyLabs and the inspiration behind developing 3D-printed compounded medications?

Topelius: CurifyLabs has developed a platform for compounding pharmacies and hospitals that automate the compounding process. Currently, it is very manual process and we have [developed more advanced] technology that tries to take away the human error from that manual way of doing things. We founded the company in 2021 and we are a Helsinki-based company from Finland. We started first in Europe, with a presence in 13 countries, and now we are in the US, primarily working with compounding and hospital pharmacies.

dvm360: What motivated the shift into the veterinary space?

Topelius: Actually, we started with veterinary applications. When we founded the company, our first application areas were veterinary formulations because we want to bring personalized, individualized therapies to patients. In the veterinary space, that need is even bigger than on the human side. The within-species variability, for instance, in dogs, is immense. Taking every species into account is very important from our point of view. We saw a lot of pull from the human side and focused there for a time. We never left the veterinary side, so we recently came out with our Good Manufacturing Practices (GMP)-manufactured veterinary basis.

dvm360: For veterinarians unfamiliar with this, how do 3D-printed compounded medications work, and how do they differ from traditional compounding?

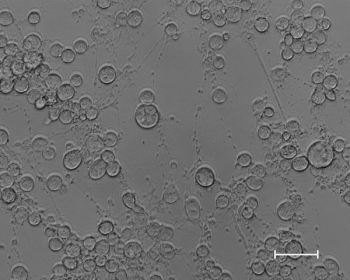

Topelius: The compounder—what we call the “Compounding System Solution” is based on and inspired on 3D printing. With this technology, you can really precisely and flexibly dose any given drug that is in the formulation library. Precision is one of the key elements. You could build dosage regimens very accurately for any given patient. These medications also have bases.

dvm360: Can you talk specifically about the CuraBlend Vet base?

Topelius: CuraBlend Vet, which we launched in December 2025, is a specifically designed excipient base into which the pharmacist adds the active pharmaceutical ingredient. This base is designed to be palatable to patients, primarily cats and dogs. We [designed] it like a gummy-like treat for optimized palatability. In essence, the base and the technology together build the dosage form, while the technology provides the precision and possibility to really individualize the dosing in an optimal way.

dvm360: Are there any upcoming developments for CurifyLabs in the veterinary market?

Topelius: This launch of the first CuraBlend Vet base, which is beef-flavored, will be accompanied by other bases. We need to broaden that spectrum of different types of flavors for more flexibility

dvm360: Looking ahead, how do you see personalized, 3D printed medications changing the way veterinarians prescribe over the next decade?

Topelius: From a treatment optimization perspective, this type of technology offers the best solution because you can really tailor the dosing. Going forward, there will be other types of formulations made available for more species beyond dogs and cats, allowing better-optimized treatment across more veterinary patients. [With conventional, manual compounding,] a tablet might need to be split into multiple pieces, usually by the pet owner.

It will also push the boundaries of individualized treatment.

Diagnostics and biomarkers, such as blood tests, could inform adjustments to a patient’s dose over time—creating something like a feedback loop that responds to the animal’s actual needs. That kind of individualized, patient-specific dosing isn’t possible with today’s conventional compounding or standard tablets, so 3D-printed medications could play a big role there.

Newsletter

From exam room tips to practice management insights, get trusted veterinary news delivered straight to your inbox—subscribe to dvm360.